Opening the doors of AM

Brad Kreger, RAPID + TCT Speaker, CEO, Velo3D Inc.

“I am pleased to announce that the Board has appointed Mr. Kreger as our permanent chief executive officer,” said Carl Bass, chairman of the Board of Velo3D Inc. That was the big news for the additive manufacturing (AM) industry on June 17 this year. The company’s press release cited “Strategic restructuring success and improved business strength over the past six months” as the reason for replacing company founder Benny Buller as CEO.

The Fremont, Calif., metal-AM provider is not alone. Fixed costs, mergers and acquisitions, collapses and reorganizations – the last few years have been a 3D printer, Velo3D as one of the many equipment manufacturers, service offices and end-users who experienced boarding problems. However, for Velo3D at least, this obstacle seems to be disappearing.

Brad Kreger has been with the company since late 2022, when he was hired as vice president of operations. He has a bachelor’s degree in biotechnology, as well as an MBA in management and business administration. With nearly three decades in the manufacturing industry under his belt, he has a lot to say on the topic, starting with an unexpected answer to a question about the relative growth of 3D printing.

Manufacturing Engineering (ME): You worked as a production manager when stereolithography (SLA), selective-laser sintering (SLS) and fused-deposition modeling (FDM) were still in their infancy, and the first machine of the metal press—the EOSINT M250—was only a year old. old. Thirty years later, what are your thoughts on the current AM capabilities and state of the technology?

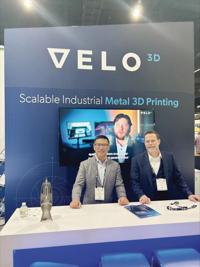

Brad Kreger and Velo3D Chief Financial Officer Hull Xu at RAPID+TCT 2024.

Both executives were recently appointed to their positions.

Brad Kreger: I’ll give you an example from the 2D printing world. Most of us remember when the first computer printers came out, and by that I mean inkjet printers for personal use. You would create a document at home, and after playing with the settings for a while, get everything looking right. But when you took the document and printed it at work or on a friend’s computer, the formatting was messed up. Either the fonts come out wrong or you have more pages than the original, and you will have to change the settings again.

Today, every print job comes out exactly as you expected, and the only question is whether the machine is out of toner. We haven’t reached that level of sophistication in 3D printing yet and we won’t gain mass acceptance until we do.

ME: Several industry analysts list Velo3D among the top 10 metal-AM companies by revenue. How did someone with a degree in molecular and cellular science become its CEO?

Krieger: To be honest, I always planned to be a biologist, but as we all know, sometimes life throws us the ball. As you may have noticed earlier, my first job after college was as a product manager for a start-up company, Affymetrix. They helped the pioneers to analyze genes in detail, and the production method of that product was very similar to that used to make semiconductor chips. Regardless, I ended up spending a lot of time in engineering and process development, working with complex hardware and software, and I was part of a team that provide the latest technology that has become commonplace.

Despite its current capabilities, Metal AM is also a new technology. It reminds me of where the genetics industry was in the 1990s. At the time it took several years and millions of dollars to sequence a person’s genome; now you can do it in 24 hours for less than a thousand dollars. I look forward to taking additive manufacturing into the same industrial era.

ME: An article in Forbes magazine from earlier this year refers to “the stress at work.” Considering everything that happened at Velo3D last year, what are your thoughts?

Krieger: In the early days of AM, there was great optimism about how it would change manufacturing and even the world. This was consistent with some not knowing how easy it would be to do so, leading people to think we would see rapid, widespread adoption. So, despite its many advantages and obvious use cases, additive manufacturing—especially steel—is a complex technology, and moving away from traditional manufacturing methods in favor of AM has proven to be more difficult. as many expected.

ME: How so? Can you provide any examples?

A lip brake produced for the US Army on Velo3D’s Sapphire XC 1MZ printer. By 3D printing the part, the US Army was able to reduce the lead time for this part from 12-18 months to just two weeks.

Krieger: Consider a machine shop or other contract manufacturer. Managers may think that they will buy a few 3D printers and add them to the company’s portfolio. As many have discovered, the skills and discipline and everything that goes along with AM is very different from what most people expected. You can’t just take a machinist or CNC programmer and turn them loose on a commercial-grade 3D printer – without extensive training at the very least. The contractors we’ve seen succeed understand that. They set up an additive manufacturing facility and brought in the skilled workers needed to work on it.

ME: Do you think that regulatory agencies are too critical of AM-produced features, thus delaying adoption?

Krieger: Having worked in other regulated environments, I have to agree with that to some extent. When you have achieved a certain level of performance or quality in a manufactured product, and you propose to change the way that product is manufactured, it becomes easier and easier for the response to be, “Hey, if we don’t change anything, you have less risk to deal with, right?” In other words, risk factors increase as a given system grows.

Despite this, look at what is happening in defense. We’re seeing increasing interest from many prime contractors, especially for MRO parts, and the US Navy has begun incorporating 3D printing into some of its ships. see submarines and carriers. It will take more time, but I think the regulatory bodies are starting to accept AM’s quality proposal and getting approved parts will be easier.

ME: One of the main features of Velo3D was the concept of the “golden” print file. Do you see that change? Alternatively, do you want to move from a closed environment to a more open one?

Krieger: The gold-printed file—along with our design and calibration process—provides portability. It is fixed, contains the operating parameters, laser commands and everything in a static and encrypted file. That, combined with our process, allows a producer to qualify a role on one machine, then take that file and print it on any of our other systems, anywhere, then you get a good part in the first attempt. That capability is unique to Velo3D, and made possible by developing hardware and software in concert. When you don’t have those things made in the same environment, it’s very difficult to get to the same level of reproduction, that’s why our quality production has proven to be fundamental and the center of the great increase of the latest demand.

Most of this comes from the DoD (United States Department of Defense), which wants to produce a list of equipment materials for their military equipment, and then print them and distribute them to various logistics facilities that are able to print when it is necessary. The biggest benefit for the DoD is that they can realize the scalability that AM has been promising and possible in relation to the cost of full production.

ME: Let me put it another way – do you want to move from a closed environment to a more open one, as many of your competitors have done?

Krieger: We recognize that many developers may need or wish to customize their own build parameters. However, more importantly, many have already made their measurements at a high level of technological readiness in other publishers and may wish to move to a system like ours, designed for scalable production. That means companies can come to Velo3D with all their existing knowledge and build on it.

To that end, we have developed a tool called Developer that allows them to unlock certain values, modify them and transfer them to other Velo3D devices within their company or perhaps to subcontract the tools. the same using a set of parameters. It comes down to creating flexibility. So it doesn’t break this gold print file paradigm, but it opens up different use cases and allows us to work with multiple clients. In fact, we have customers who have used Designer and have been able to maintain the functionality of the gold print and the scalability it provides.

ACP1 fan blade printed using laser powder bed fusion. The part, produced on a Velo3D Sapphire printer, is 300 mm wide and is shown in its printed state.

ME: Would you like to share some final thoughts?

Krieger: As I mentioned before, I have a background in biology and genetics. The equipment used in that industry shares several similarities with 3D printing in that both are large, highly complex devices that combine many technical disciplines and marry them to produce a complex result.

However, there is no panacea. For example, steel AM does not replace machining as many have expected. They are two parts of the same environment. And, like genomics, its practitioners must understand the use cases before they can effectively use its potential. So I think the whole industry right now is going to redefine additive manufacturing. What is its significance? And how will we use it? Looking ahead, we still have a lot to learn, but I am very optimistic about the future of AM and manufacturing in general.

#Opening #doors