Basics of thermal simulation for additive manufacturing – Engineering.com

The first tool for engineers to simulate thermal phenomena in 3D printing.

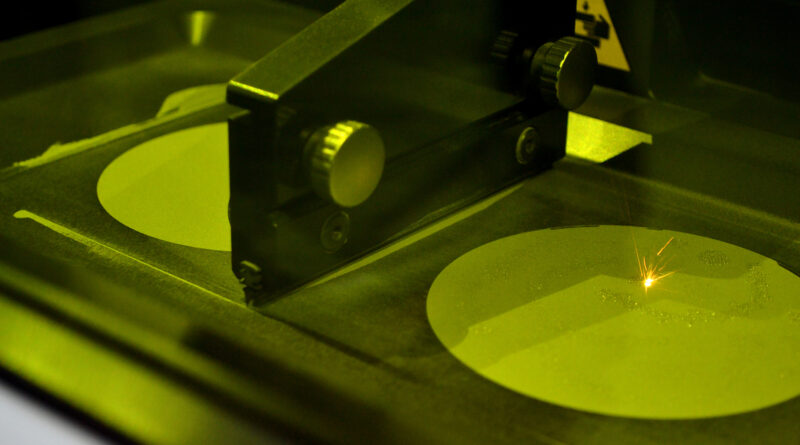

Many additive manufacturing (AM) processes involve using thermal energy to combine feedstocks into 3D printed parts, layer by layer. Although this method allows more complex internal geometries than traditional methods, such as casting, molding or machining, it can also produce anisotropic material properties and residual stresses due to variable heating and cooling in 3D printed parts, which can cause hardening or grain growth in the material, especially in metal AM processes.

This can make the mechanical properties of 3D printed parts inconsistent, as well as affect print speed – due to the need to account for temperature fluctuations across the part – and reduce quality surface and dimensional accuracy.

That’s why it’s important for engineers to understand the thermal history of an additive, as that determines its microstructure, its mechanical properties and its final size. Thermal simulations can help improve these key performance indicators (KPIs) by modeling thermal history without the need to print 3D test sections.

What is involved in thermal simulation for additive manufacturing?

While the different types of processes will depend on the specific additive manufacturing process being simulated, in the case of laser powder bed fusion (L-PBF), for example, these include:

- Laser power

- The width of the laser spot

- Laser conversion

- Scan head speed

- Layer thickness

In this case, the thermal history of the part affects the size of the melt pool, defect structure, solid state, melt cycles and residual stress. What makes AM simulation even more challenging is the fact that it requires the analysis of temperature changes on sub-nanosecond timescales, which are orders of magnitude shorter than the overall build time. Because of this, L-PBF temperature simulations can take hours or days to complete.

How do materials affect temperature simulations for AM?

Next to the unique additive manufacturing process, the materials being printed in 3D will have a big impact on the thermal simulation for AM.

For metals used in L-PBF or direct deposition (DED), their high thermal conductivity allows rapid heat dissipation, which can lead to thermal gradients across the part and cause residual stress that can result in fighting or twisting. Steels also undergo solid state changes during cooling, such as martensitic changes in stainless steel. Apart from these general factors, there are also specific alloy factors for the thermal simulation of AM steel: for example, titanium alloys are very reactive and oxidize easily, so they need controlled air when aluminum tends to dissolve.

On the other hand, polymers used in fused deposition modeling (FDM) or selective laser sintering (SLS) show low thermal conductivity, resulting in a slow cooling rate and a high tendency for residual thermal stress or to fight. This is particularly problematic for semi-crystalline polymers, such as nylon, where slow cooling can result in the formation of crystals that affect mechanical strength. Polymer materials are also vulnerable to thermal degradation due to excessive heat, which can cause brittleness or off-gassing. Finally, simulations involving 3D printing and thermosets (as opposed to thermoplastics) must also account for the effects of the healing process.

How do you make a thermal simulation for 3D printing?

Thermal simulations often use numerical methods due to the complexity of the phenomena they model – for example, using finite element analysis for heat transfer during metal deposition.

However, the speed of many 3D printing methods, combined with the complexity of temporal and temporal thermomechanical phenomena make the computational cost of numerical modeling for AM high especially when trying to simulate the entire temperature history of the part. Because of this, FEA is often too complex and time-consuming to be useful during manufacturing. Reduced modeling (ROM) and hybrid methods that combine the finite element method (FEM) with other methods are emerging to solve this computational cost problem, but at the time of writing these are still in their early stages. development.

Finally, the comparative analysis of productivity can be understood as a multidimensional problem in time and space. From this perspective, engineers can control the size of the simulation and the fidelity of the solution by choosing time increments and mesh sizes.

When considering the quantity, simulations of a process level with small increments and fine meshes are more reliable, compared to simulations of a certain level with a time-scaled sequence of events and meshes it is coarse, which is weak integrity. In the first case, the simulations are intended to capture the rapidly changing temperatures and high temperature gradients found in and around areas where active melting or fusion occurs. Finally, temperature results often do not have accurate temperature history, although heat transfer analysis can still capture changes away from active areas, as long as heating and cooling heat capacity measurements are made. correctly.

Modeling heat transport phenomena in AM systems is complex, needing to account for moving heat sources, phase transitions and different heat and heat transfer conditions. However, when done correctly, thermal simulations can help design and manufacturing engineers make design changes to ensure uniform cooling, develop supports to reduce pressures or change parameters. of operations to reduce the risk of errors.

#Basics #thermal #simulation #additive #manufacturing #Engineering.com